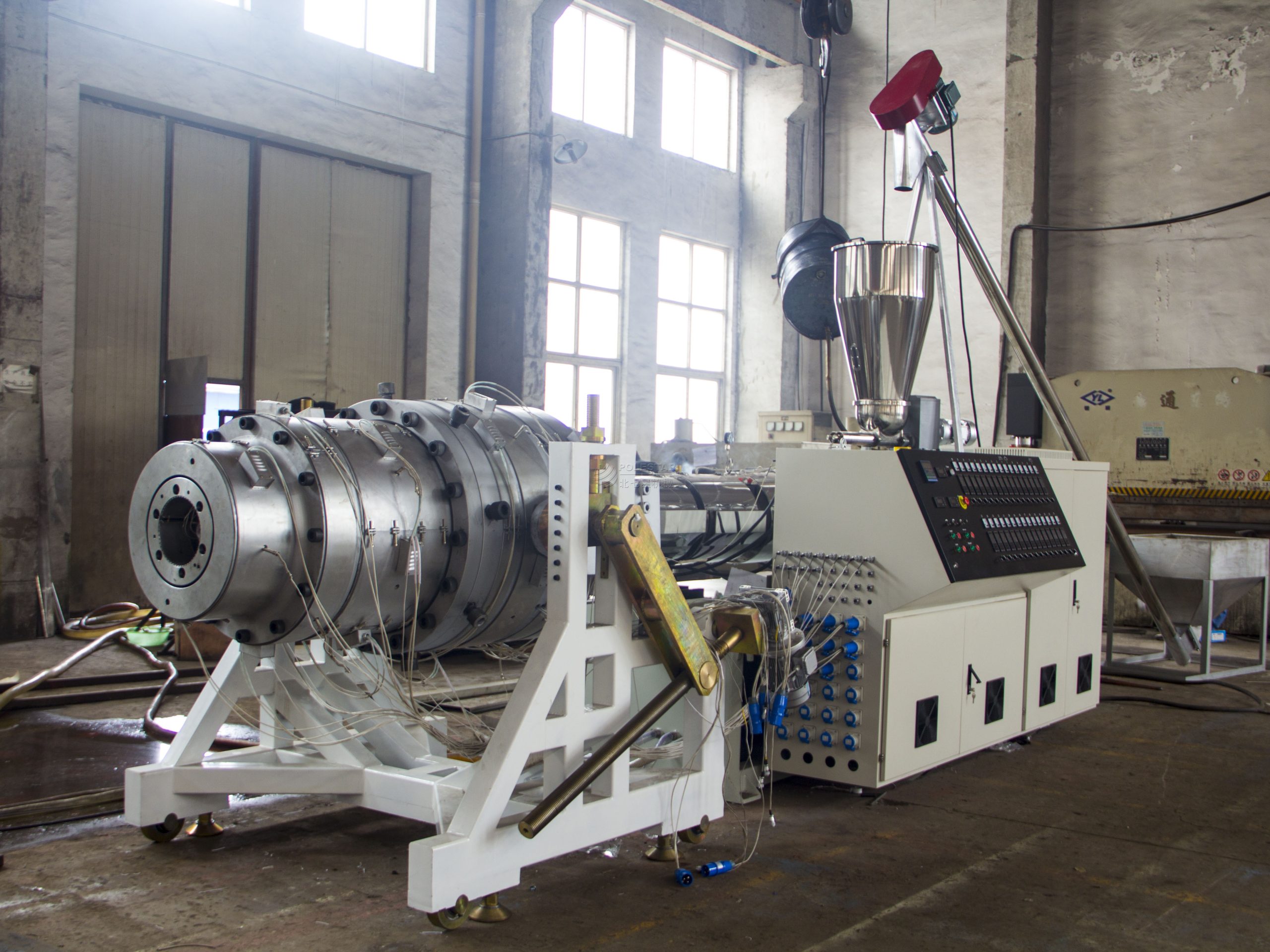

SJZ Series Conical Twin Screw Extruder

Machine Characteristics

SJZ series conical twin- screw extruder has advantages such as forced extruding, high quality,wide adaptability ,long working life,low shearing speed,hard decomposition,good compounding & plasticization effect,and direct shaping of powder material and etc. Long processing units ensure stable processes and very reliable production in many different applications. You profit from high output, consistently excellent product quality and an outstanding performance ratio-over the whole performance range.

This extruder is suitable for matching with production line of plastic pipe, plate and profile and etc.

1.Available to rigid and soft PVC included C-PVC

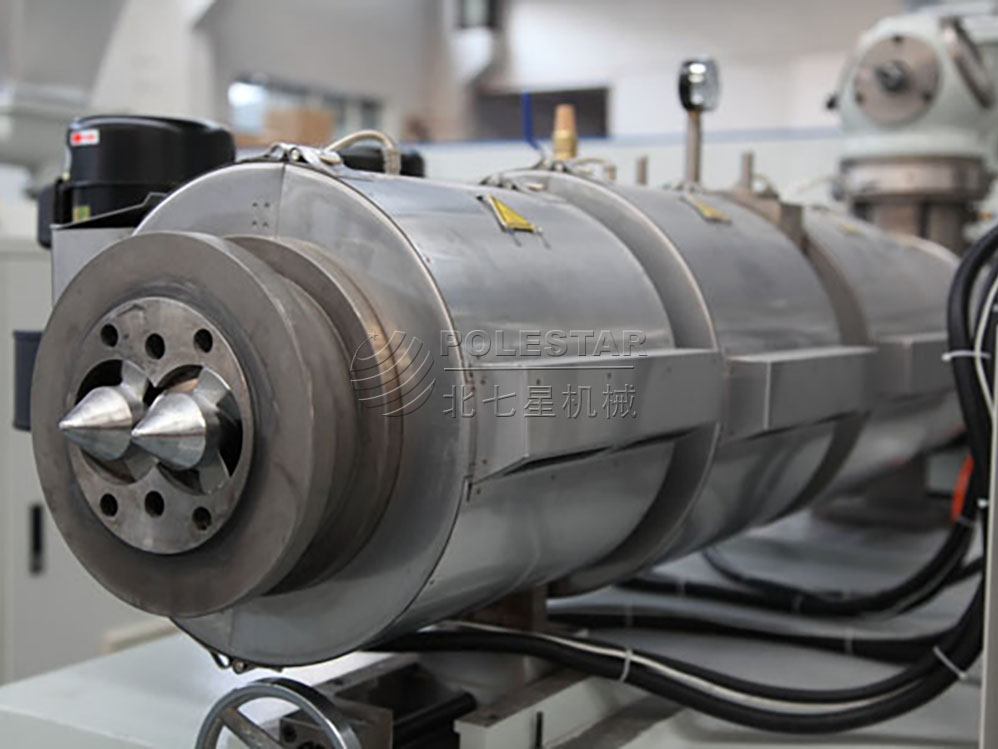

2.Unique screw design to achieve higher plasticizing and products quality

3.Core self-circulation temperature control for screw. More accurate temperature control system

4.Gearbox of high torsion balance to realize stable running, low oil temperature available

5.Automatic and visible circulation system of lubricant on gear box

6.H shape frame to decrease vibrating

7.PLC (Simatic Multi Panel) operation panel to ensure synchronization.

8.Energy conservation, easy to maintenance

1.Available to rigid and soft PVC included C-PVC

2.Unique screw design to achieve higher plasticizing and products quality

3.Core self-circulation temperature control for screw. More accurate temperature control system

4.Gearbox of high torsion balance to realize stable running, low oil temperature available

5.Automatic and visible circulation system of lubricant on gear box

6.H shape frame to decrease vibrating

7.PLC (Simatic Multi Panel) operation panel to ensure synchronization.

8.Energy conservation, easy to maintenance

Technical Data

| Model Parameter | SJZ51 | SJZ65 | SJZ80 | SJZ92 | SJZ105 |

| Screw DIA(mm) | 51/105 | 65/132 | 80/156 | 92/188 | 105/216 |

| Qty of screw | 2 | 2 | 2 | 2 | 2 |

| Screw direction | Opposite and outer | ||||

| Screw speed(rpm) | 1-32 | 1-34.7 | 1-36.9 | 1-32.9 | 1-32 |

| Screw length(mm) | 1070 | 1440 | 1800 | 2500 | 3330 |

| Structure | Conical mesh | ||||

| Main motor power(kw) | 18.5 | 37 | 55 | 110 | 185 |

| Total power(kw) | 40 | 67 | 90 | 140 | 255 |

| Output(max: kg/h) | 120 | 250 | 360 | 800 | 1450 |

| Qty of barrel heating zone | 4 | 4 | 4 | 5 | 6 |

| Feeder | Screw dosing | ||||

| Center height of machine(mm) | 1000 | 1000 | 1000 | 1100 | 1300 |