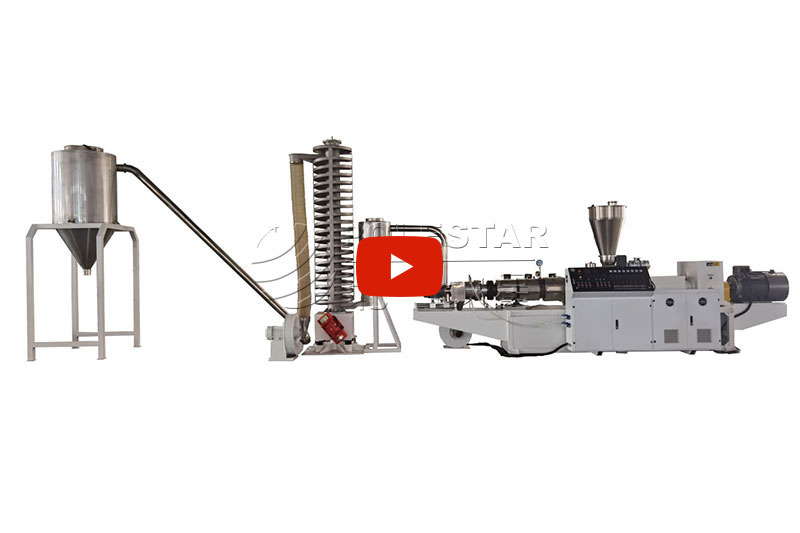

PVC Double Screw Conical Granulating Line

Description

The PVC Double Screw Conical Granulating Line is a specialized machine used in the plastic recycling industry to process PVC materials into granules.

This granulating line consists of a twin-screw extruder with a conical design, which allows for efficient mixing and compounding of the PVC material. The conical shape of the extruder provides increased pressure and temperature control, resulting in better quality and consistency of the granules produced.

Technical Parameter

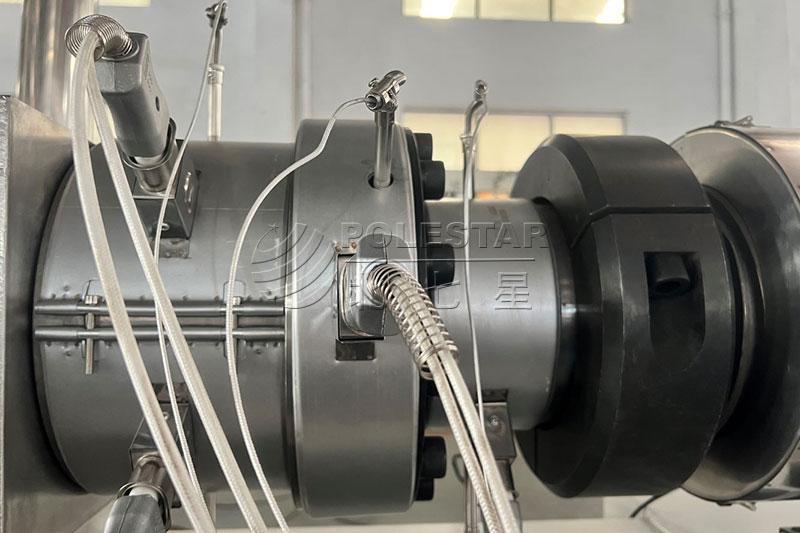

1.SJZ80/156 Conical Twin Screw Extruder

Diameter conical 80/ 156 MM

Rotating speed (counter rotating): RPM

Motor power: 55 KW

Barrel heating power: 32 KW, 4 heating zones

Cooling mode: Air fans: 3 Sets

Feeding motor: 0.75 KW

ABB Inverter

2.Mould and die-cutting

Mould surface material: 38CrMoAlA

3.Pelletizing System

Cutting blade material: 9CrSi

Cutting holes diameter: 3.8-4 MM

Cutting motor power: 2.2 KW

4.Wind Conveyor

Air blower: 2.2KW

Material of pipe: stainless steel

5.Lift Vibrating Cooling Machine

Motor Power:0.75 KW*2 sets

Discharge Outlet Height: 1100 MM

Diameter: 630 MM

Capacity: 750 kg/hour

6.Wind conveyor Storage Silo

Air Blower: 2.2 KW

Discharge distance from the ground: 1350 MM

Volume: 300L

Function

The function of the PVC Double Screw Conical Granulating Line is to melt, mix, and extrude the PVC material into uniform granules of a specific size. These granules can then be used in various applications, such as injection molding, extrusion, or blow molding, to create new plastic products.

Overall, the PVC Double Screw Conical Granulating Line is a versatile and efficient machine that plays a crucial role in the recycling and reuse of PVC materials, helping to reduce waste and promote sustainability in the plastic industry.

Overall, the PVC Double Screw Conical Granulating Line is a versatile and efficient machine that plays a crucial role in the recycling and reuse of PVC materials, helping to reduce waste and promote sustainability in the plastic industry.