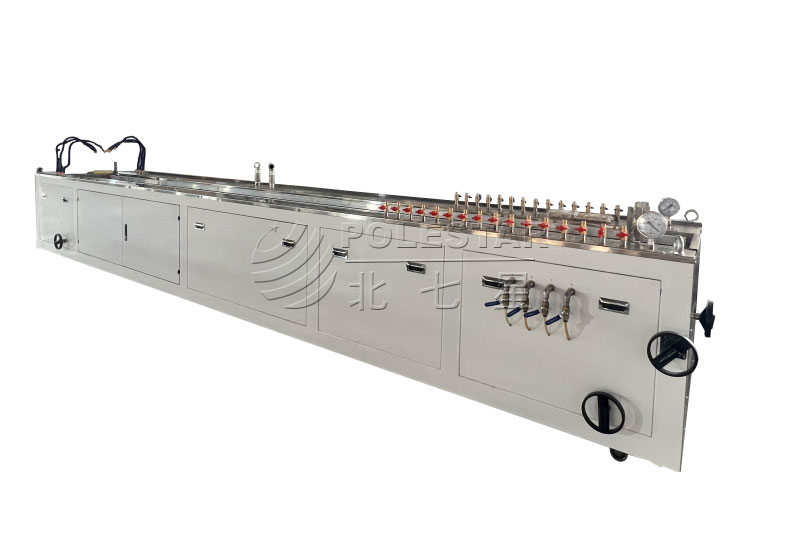

Plastic Profile Vacuum Cooling Tank

Description

The vacuum cooling tank is an essential component in the extrusion process for plastic profiles. Its primary function is to rapidly cool and solidify the newly extruded plastic profile using the principles of vacuum and water cooling. Here are some key functions of the vacuum cooling tank for plastic profiles:

Sizing and Shaping: The vacuum cooling tank aids in maintaining the dimensional accuracy and shape of the plastic profile by controlling the cooling process. This helps ensure that the profile meets the required specifications and tolerances.

Water Cooling: the tank incorporates water cooling, where the profile is immersed in a water bath ensures efficient and uniform heat extraction, reducing its temperature rapidly.

Sizing and Shaping: The vacuum cooling tank aids in maintaining the dimensional accuracy and shape of the plastic profile by controlling the cooling process. This helps ensure that the profile meets the required specifications and tolerances.

Water Cooling: the tank incorporates water cooling, where the profile is immersed in a water bath ensures efficient and uniform heat extraction, reducing its temperature rapidly.

YDF300 Model Technical Parameter

YDF400 Model Technical Parameter

YDF600 Model Technical Parameter

- Tank length: 9000 MM

- Tank width: 1400 MM

- Tank material: 2MM thickness stainless steel

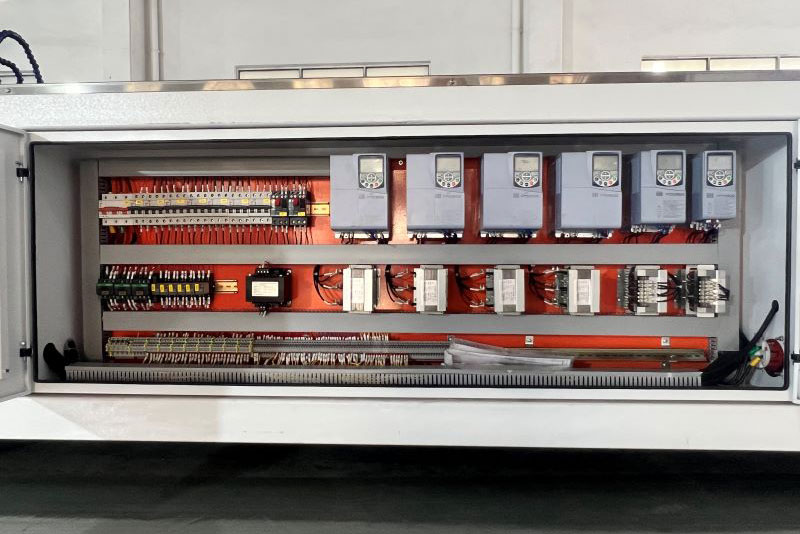

- Vacuum pump power: 5.5 KW*3

- Water pump power: 4KW

- Vacuum nozzles quantity: 24 PCS

- Water nozzles quantity: 24 PCS

- Air blower motor power: 1.1 KW

- Forward and backward move motor power: 1.5 KW

- Tank upward and downward movement by motor

- Tank horizontal inclination and lef/right movement can be adjusted manually

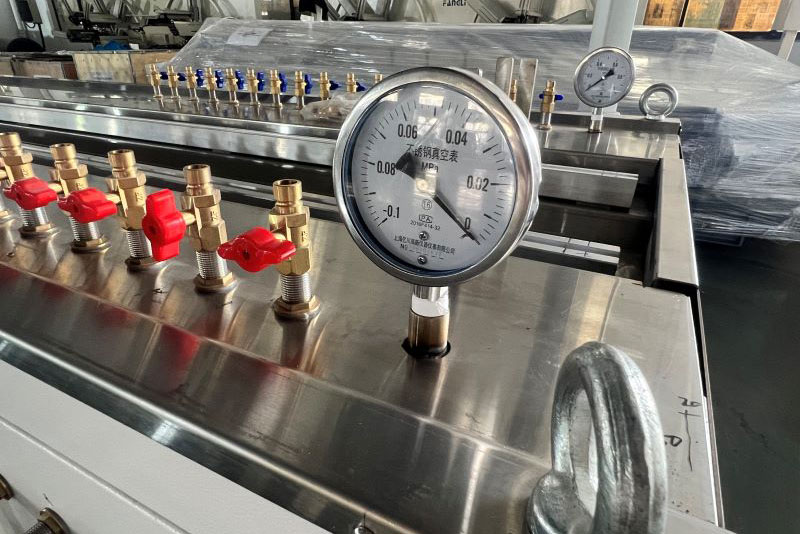

- The vacuum gauge and water pressure gauge display the vacuum degree and water pressure