Main Function and Description

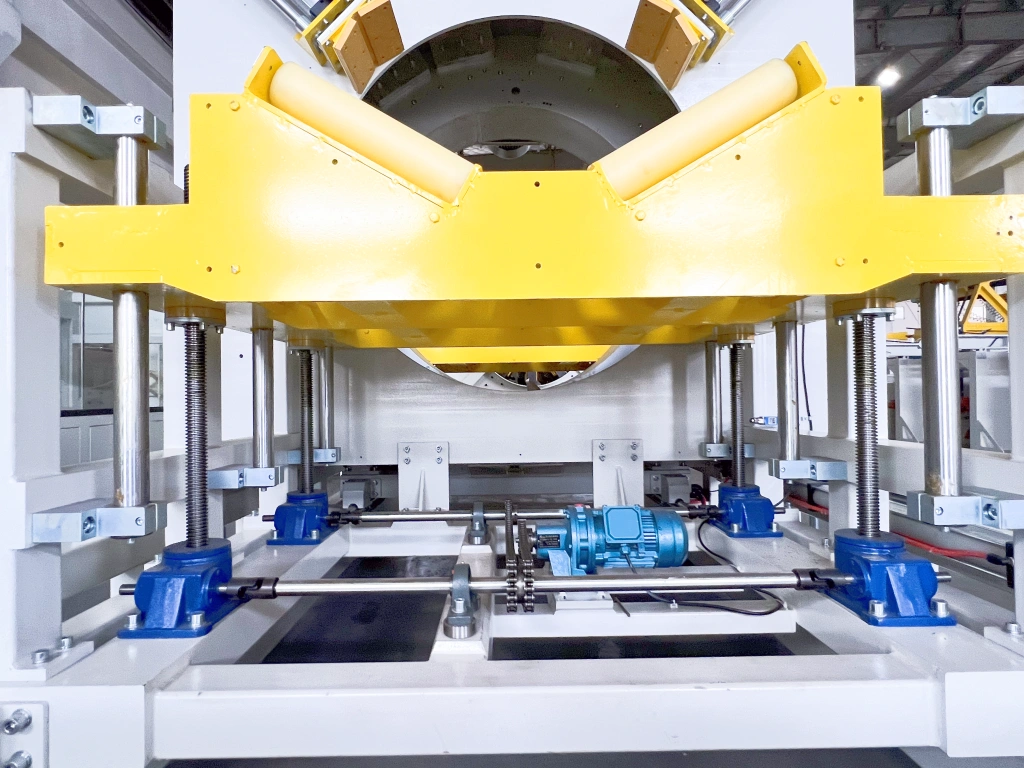

The PE chip-free cutting machine is a specialized piece of equipment designed for cutting polyethylene (PE) pipes with diameters ranging from 900 mm to 1200 mm. This machine is essential in the manufacturing and processing of large-diameter PE pipes, ensuring clean and precise cuts without generating chips or debris, which is crucial for maintaining the integrity of the pipe.

1. Chip-Free Cutting: The primary function of the PE chip-free cutting machine is to provide clean cuts on PE pipes without producing chips or shavings. This is particularly important for maintaining the quality of the pipe ends, which are often used for welding or joining.

2. Precision and Accuracy: The machine is designed to deliver precise and accurate cuts, ensuring that the lengths of the pipes meet the required specifications. This precision is vital for applications where exact measurements are critical.

3. High Efficiency: The cutting process is optimized for high-speed operation, allowing for quick and efficient production. This is especially beneficial in high-volume manufacturing environments where time is a critical factor.

4. Versatility: The machine can accommodate various wall thicknesses and pipe lengths, making it versatile for different production needs. This adaptability allows manufacturers to work with a range of PE pipe products.

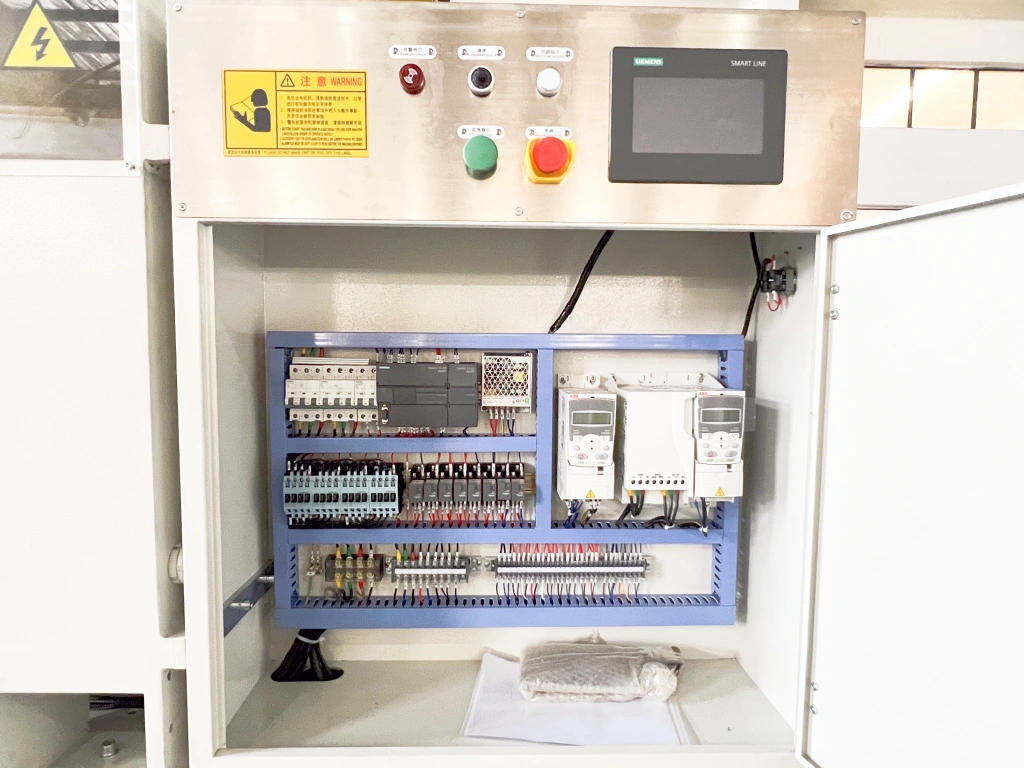

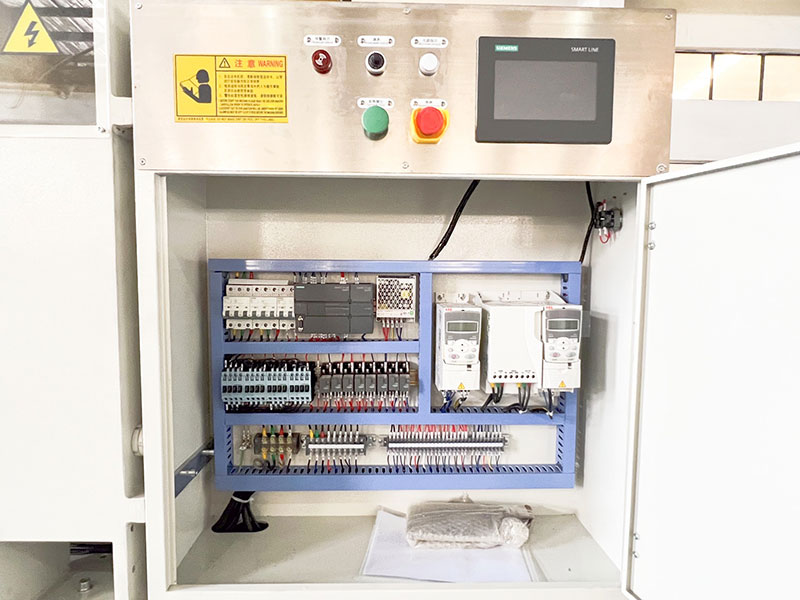

5. Safety Features: Modern PE chip-free cutting machines are equipped with safety features to protect operators during the cutting process. This may include emergency stop buttons, safety guards, and automatic shut-off systems.

6.Control Panel: A user-friendly control panel is integrated into the machine, allowing operators to monitor and adjust settings easily. This panel may include digital displays for length measurement, speed control, and operational status.

7.Dust and Debris Management: To maintain a clean working environment, many PE chip-free cutting machines include systems for managing dust and debris generated during the cutting process, ensuring a safe and tidy workspace.

Main Technical Parameters:

1. Cutting pipe range: Φ900~1200 MM

2. pipe cutting thickness: 110MM

3. Cutting motor power: 5KW

4. Blade feedmotor power: 1 KW*2

5. Cutting blade size: 215*80*5 MM

6. Nylon roller height adjust motor power: 0.75 KW