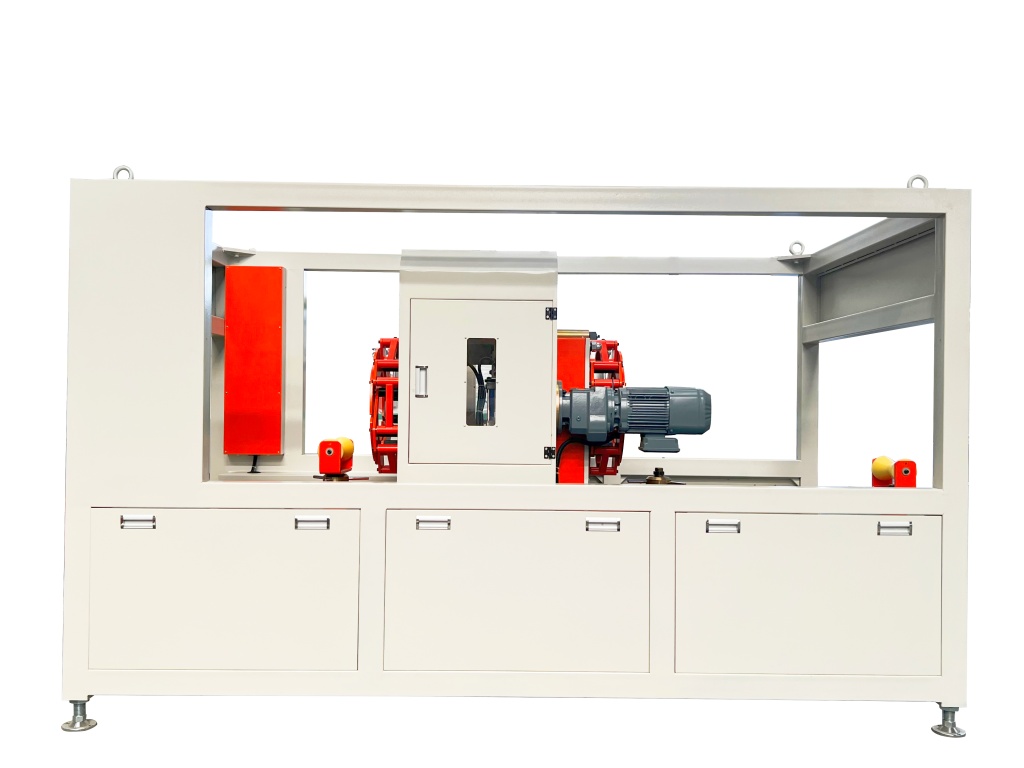

Main Function and Description

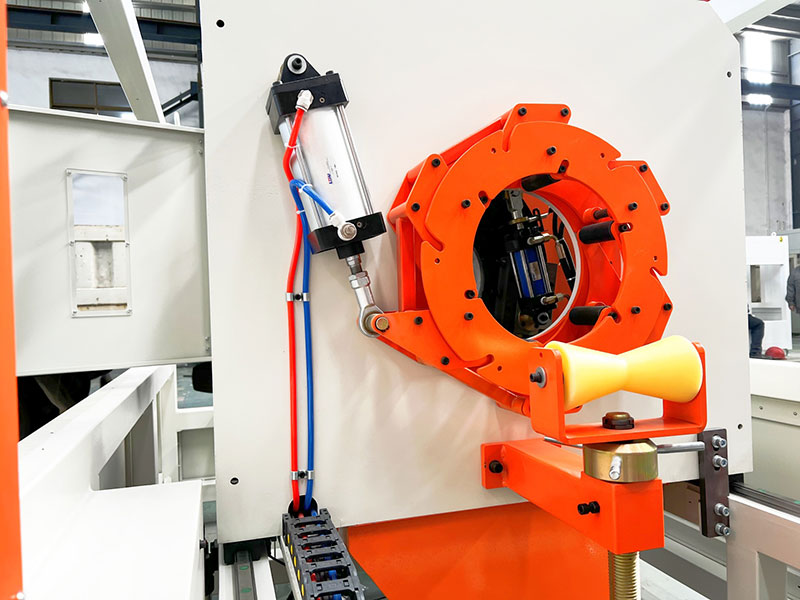

The PVC planetary cutting machine is a specialized piece of equipment designed for cutting PVC pipes with diameters ranging from 63 mm to 250 mm. This machine is essential in the plastic pipe manufacturing process, ensuring precise and efficient cutting of pipes to the desired lengths for various applications.

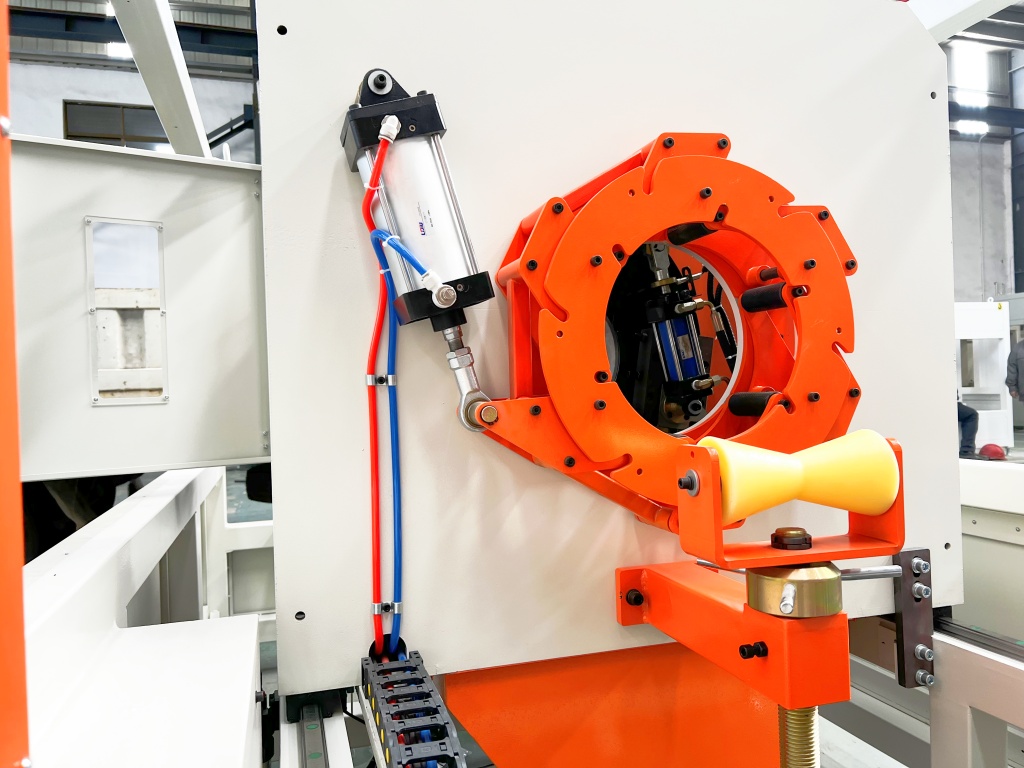

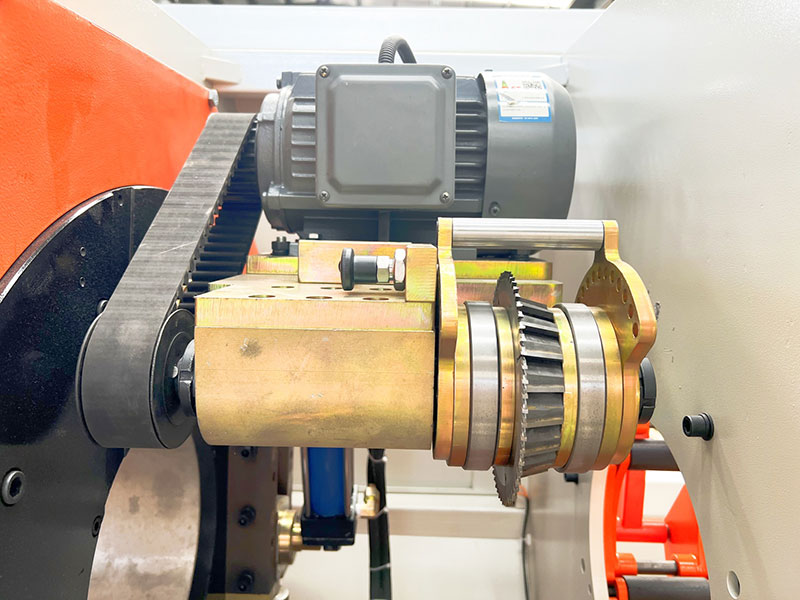

1.Precision Cutting: The primary function of the PVC planetary cutting machine is to provide accurate and clean cuts of PVC pipes. The machine is designed to handle various pipe sizes within the specified range, ensuring that each cut meets the required length and quality standards.

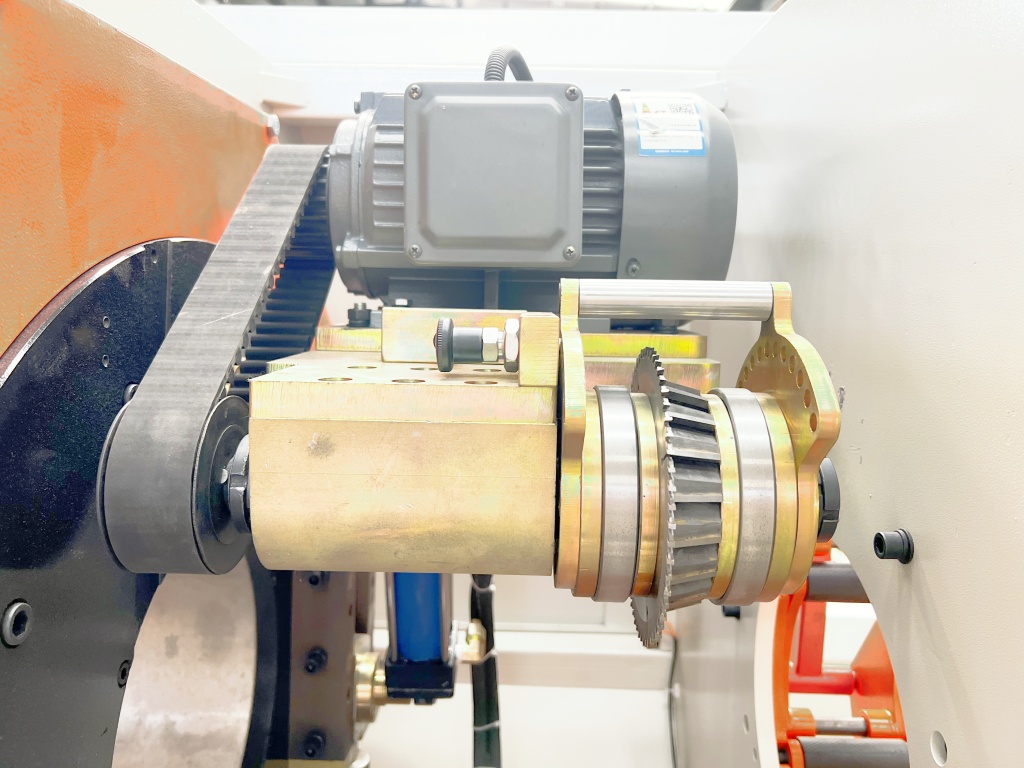

2.High Efficiency: The planetary cutting mechanism allows for high-speed cutting, which increases production efficiency. This is particularly important in high-volume manufacturing environments where time and productivity are critical.

3. Versatility: The machine can be adjusted to cut different pipe diameters and wall thicknesses, making it versatile for various production needs. This adaptability allows manufacturers to work with a range of PVC pipe products.

4. Minimized Waste: The cutting process is designed to minimize material waste. By ensuring precise cuts, the machine helps manufacturers optimize their raw material usage, reducing costs and environmental impact.

5. Safety Features: Modern PVC planetary cutting machines are equipped with safety features to protect operators during the cutting process. This may include emergency stop buttons, safety guards, and automatic shut-off systems.

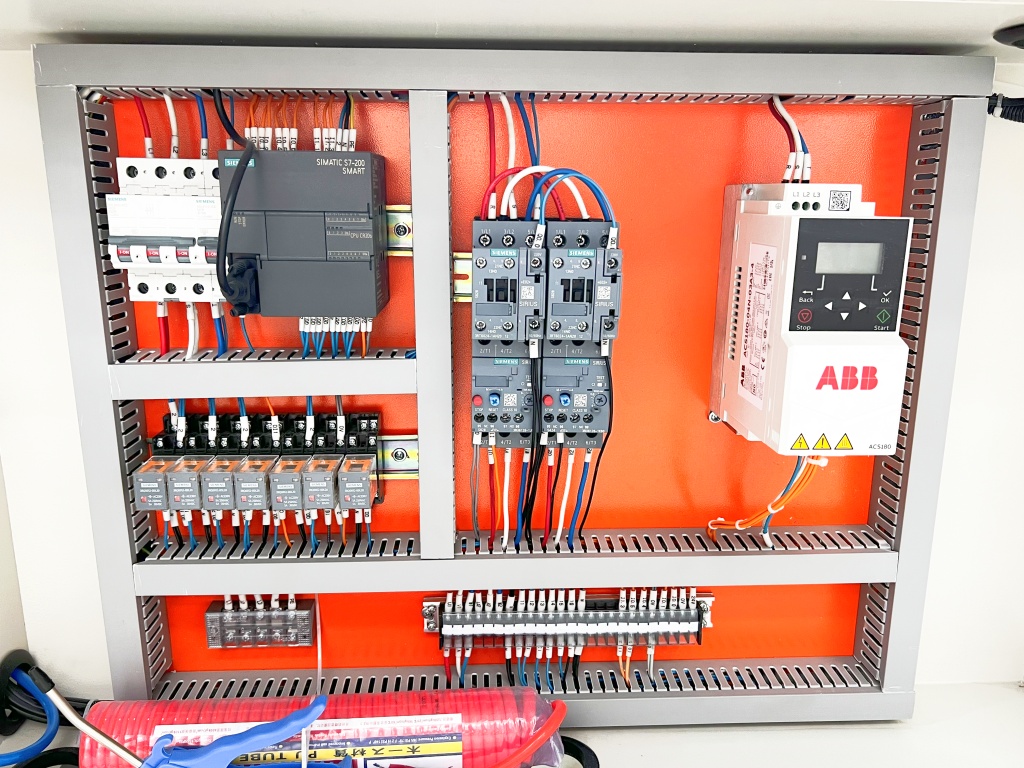

6.Control Panel: A user-friendly control panel is integrated into the machine, allowing operators to monitor and adjust settings easily. This panel may include digital displays for length measurement, speed control, and operational status.

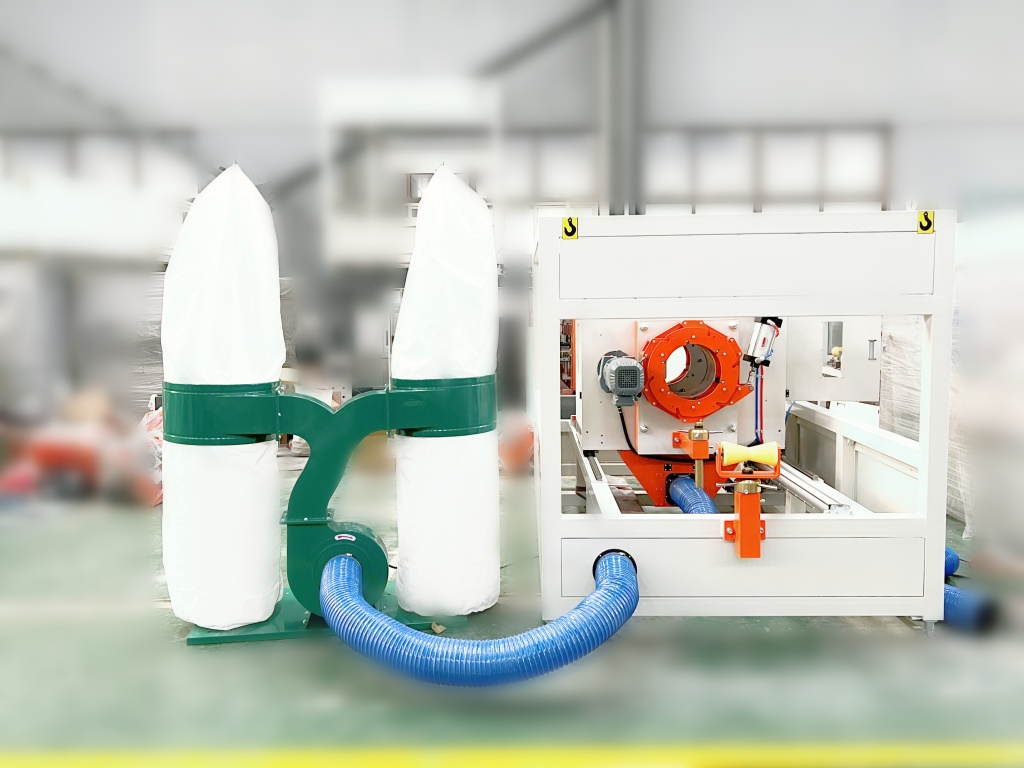

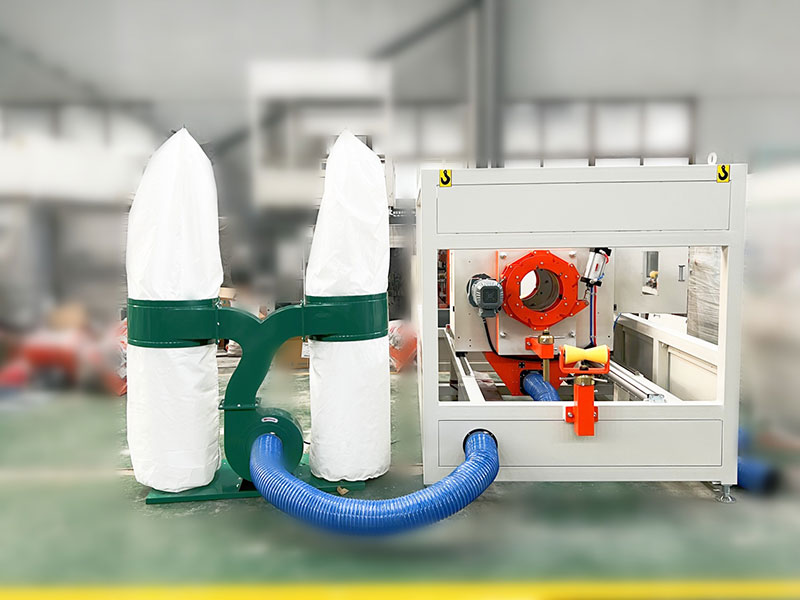

7.Dust and Debris Management: To maintain a clean working environment, many PVC planetary cutting machines include dust extraction systems that remove debris generated during the cutting process.

Main Technical Parameters:

1. Cutting pipe range: Φ63~250 MM

2. Max. pipe cutting thickness: 25 MM

3. Revolution motor power:1.1 KW

4. Cutting motor power: 2.2 KW

5. Oil pump motor power: 0.75 KW

6. Suction fan power: 3.0 KW

7. Chamfering device: Φ120xФ30×25 MM

8. Cutting blade size: Ф150xФ30×2 MM