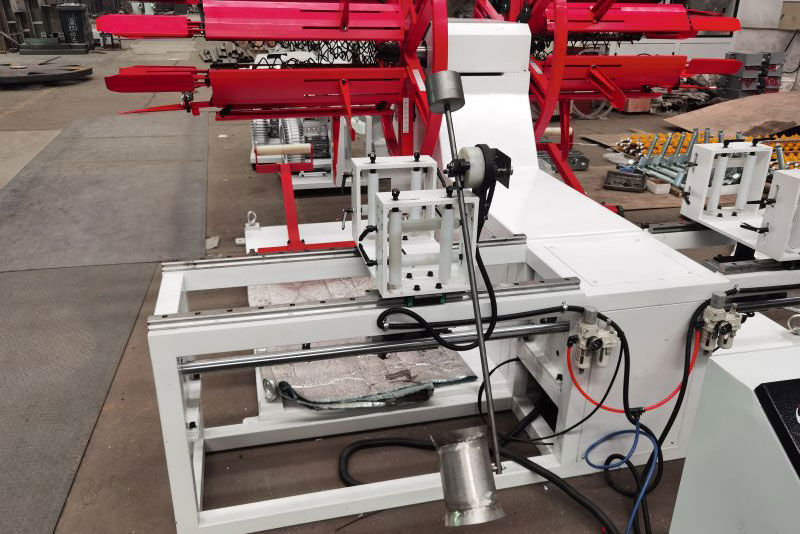

50~110MM Double Station Corrugated Pipe Winder

Description

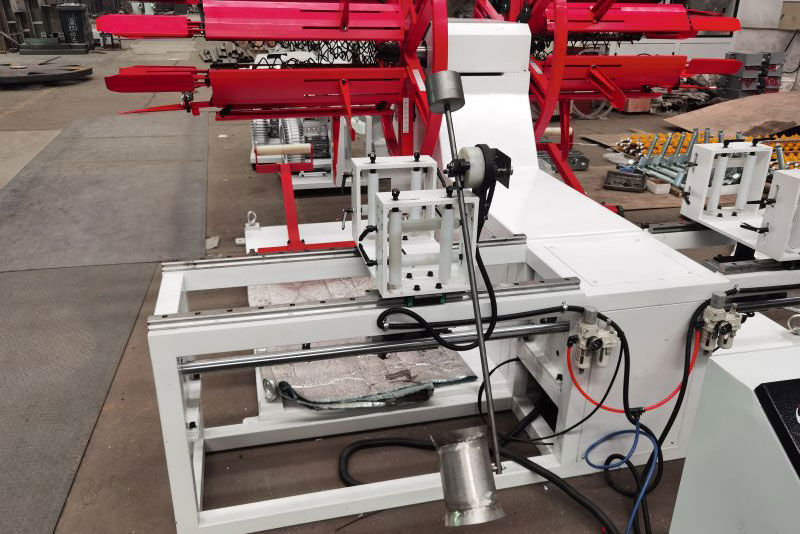

The Double Station Corrugated Pipe Winder is a machine used for winding corrugated pipes in a manufacturing or processing line. Its main function is to neatly and efficiently wind the corrugated pipes onto spools or reels for storage or transportation. This helps in organizing and managing the corrugated pipes, making them easier to handle and store.

The double station design allows for continuous winding without the need to stop the production line, thereby increasing efficiency and productivity. Overall, the machine plays a crucial role in the production process of corrugated pipes by providing a reliable and automated method of winding the finished product.

The double station design allows for continuous winding without the need to stop the production line, thereby increasing efficiency and productivity. Overall, the machine plays a crucial role in the production process of corrugated pipes by providing a reliable and automated method of winding the finished product.

Technical Parameter

- Pipe range: Φ50~110 MM

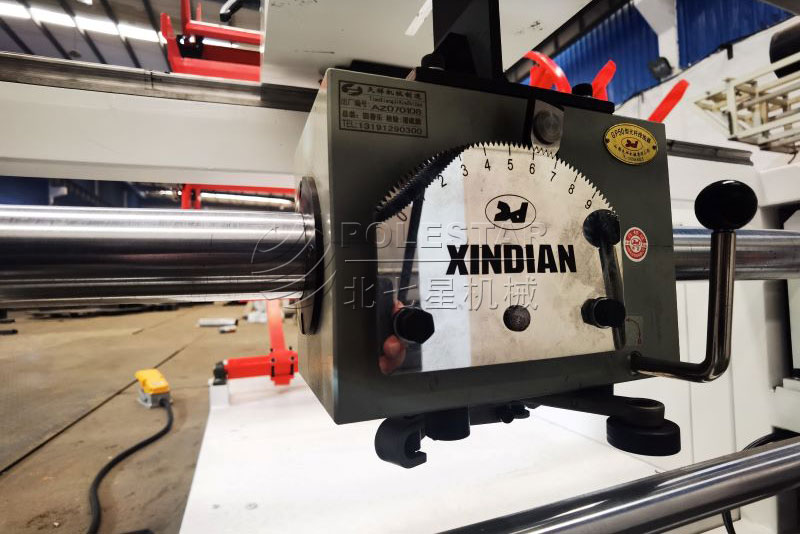

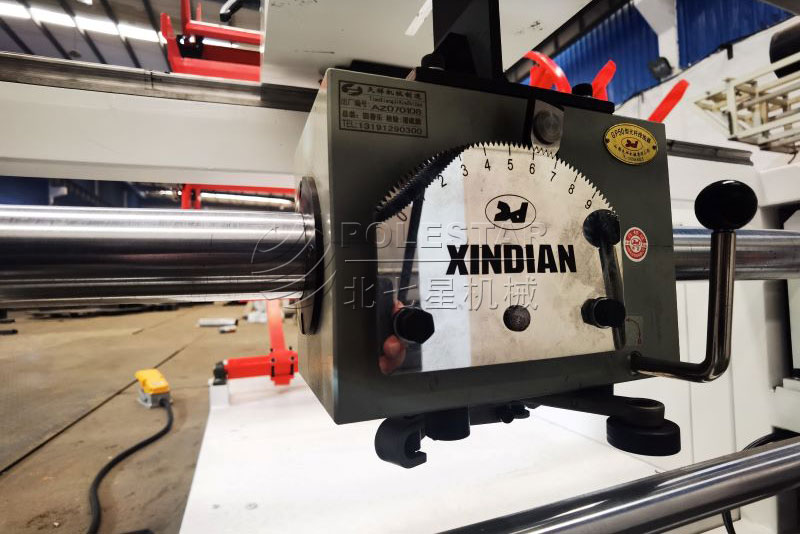

- Inner diameter: 480~650MM (adjusted by manual)

- Outer diameter: 1300 MM

- Roll up width: 450~800MM

- Pipe winding speed: 1~6 M/Min.

- Main motor power: 1.5 KW*2

- Air pressure: 3-0.6Mpa

- Pipe windingmethod: Polished rod cable (mechanical)